Editor’s note: The following column based on an interview with Alex Glasmacher, managing director of ELOKON, is part of Modern’s Other Voices column, a series featuring ideas, opinions and insights from end-users, analysts, systems integrators and OEMs. Click here to learn about submitting a column for consideration.

There is an acronym in the automotive world that is spreading into material handling. ADAS, or advanced driver assist systems, is a very exciting area, especially in terms of product development for improving safety and fleet productivity.

Unfortunately, when you talk about ADAS in automobiles the attention span goes up, but when you tell people it’s for forklifts, automatic guided vehicles (AGV) and autonomous mobile robots (AMR) the attention span goes down. The fact is that autonomous driving and digitalization are two big trends that aren’t going anywhere. When we look at what we and competitors are doing now we can see wireless, cloud and sensor technology development bringing a lot of new and exciting products in coming years. The industry is systematically working to leverage trends in digitization by looking at how our products help make the use of AGVs, AMRs, etc., safer for logistics applications.

We also see an evolution of our customer base. We see increased use of AGVs – the oldest acronym – as well as AMRs, cobots and a lot more forklifts either fully automated or augmented with automation. Bigger companies embrace these technologies, but there is increasing demand from smaller companies because of significantly higher awareness that these types of products are available. A few years ago many didn’t know, but once they start researching, we see strong awareness and adoption.

Safety is an overriding concern. Most customers are medium or large and many have a safety director and tend to take site safety very seriously. And if they operate across multiple sites, they are more likely to standardize across them. I’ve been in the industry for many years, and on the fleet management side it’s relatively easy to show a customer the return on investment (ROI) calculation. Identify costs for operators, vehicles, maintenance and energy, and then you can show that fleet management solution X, based on experience, can reduce a fleet by four vehicles and produce an ROI in 11 months.

On the safety side, it can be very difficult to quantify the benefit of something like a simple driver assist system with automatic obstacle detection and slowdown. All the same, it’s something we take very seriously, because many customers have strong safety requirements that don’t require that hard ROI.

We see very strong awareness for proximity detection sensors for reach and counterbalance forklifts in the United States as well as Europe. It’s a simple way to make free-driving trucks safer. Trucks can warn one another and pedestrians, or pedestrians can carry a badge that will warn other pedestrians and nearby forklifts, which can then automatically slow or stop.

There is a lot of opportunity in wearables. By integrating electronics into worker clothing to facilitate employee safety, it’s possible to avoid some of the hassle of conventional badges. You can’t expect 3PL providers who come into sites to all carry badges. As it moves from prototype to a product, a wearable hi-vis safety vest integrates the features of a badge. This is just one of many safety opportunities from combinations of wearables and forklift technologies.

You can even connect into older equipment. Automatically adjusting creep speed would require a forklift with at least a two-speed controller, but for the most part we try to engineer products to be retrofittable. If a third-party device is installed, it’s possible to lose conformity of a CE cert for example, but the industry is working on standardized interfaces for third party equipment. It’s important to maintain UL and CE standards agreed upon by lift truck manufacturers, and there is now a standard promoted by a prominent engineering association that is working to bring it international.

It’s very important to make sure the regulatory framework keeps abreast of new technology. Autonomous driving is already happening, and the framework in Europe – the European Machinery Directive – will likely inform developments stateside. We need to make it sure includes chapters on safety and assistance systems and a framework to apply technology to new and retrofitted lift trucks.

It’s an exciting time, and we will see a lot of great advances as a result of the two mega trends of automatic driving and digitalization.

Ergonomics and Safety Products and Accessories

SafeKey Lockout Padlocks

SafeKey Lockout Padlocks

Lockout padlocks avoid unwanted key duplication issues.

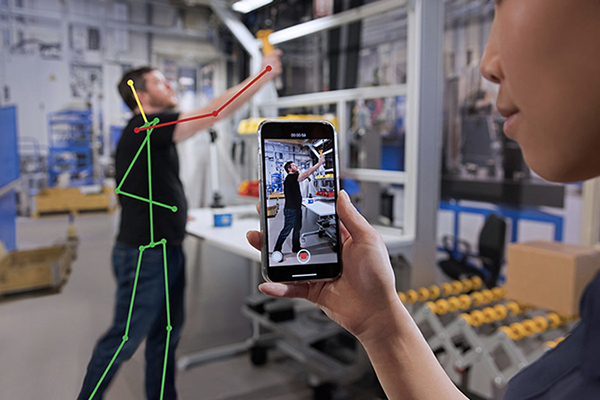

Humantech all-in-one system

Humantech all-in-one system

Minimize injuries with workplace ergonomics evaluation.

GraphEx G45100 Cut Resistant Gloves with AxiFybr

GraphEx G45100 Cut Resistant Gloves with AxiFybr

Prevent cuts to hands with safety glove.

OutdoorScan3 safety scanner

OutdoorScan3 safety scanner

Safety laser scanner certified for outdoor applications.

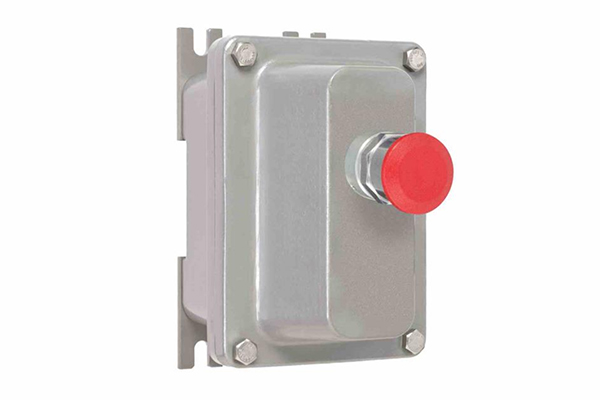

Explosion proof emergency stop switch

Explosion proof emergency stop switch

Explosion-proof emergency stop switch rated for hazardous areas.

KleenGuard personal protective equipment

KleenGuard personal protective equipment

Recyclable line of personal protective equipment.

Article topics